Which motorcycle helmet certification is the best? DOT, Snell, ECE, or SHARP?

We are here to speak to the long-debated issue of which safety rating is better and what they mean. I promise to keep this article to the point and give you both defining terms and some objective experiences, without any personal biases or #fakenews. The topic of what each rating tests and how each one is better than the other blah blah has gone on since the adoption of more ratings than the stand-alone DOT and could fill more pages than the dictionary.

Wear a Helmet

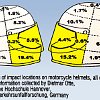

First off, helmets save motorcyclists' lives. If you have a different thought on it, it's OK to be wrong. In 2015, the use of motorcycle helmets saved an estimated 1,772 lives and 740 lives could have been spared had the motorcyclist worn a helmet. Another fact that most don't like to hear is that full-face helmets are considerably more safe. In fact, 45% of all impacts happen right in the chinbar or face area.

There are multiple styles for a reason and it's great to have choices. 1/2 shell, open-face 3/4, modular, and full-face are all better options than none and as you gain more coverage, safety tends to follow.

Anatomy of a Helmet

Before understanding the safety certifications and how they test, it's good to know what actually makes up a helmet.

Shell: The frame and overall structure of your helmet. The first line of defense in an impact. Helmet shells are made from several materials all with their own characteristics. It's good to note some of the debate about different shells. The argument is based off of energy absorption and how a more flexible shell can absorb more energy than a more rigid design. The opposing argument is that a more rigid design prevents piercing or cracking upon impact. Whichever camp you find yourself in, make sure to base your viewpoints on helmet safety on the whole picture.

- Polycarbonate (plastic): Polycarbonate is a cost-effective material that is also lightweight. Polycarbonate shells tend to be more flexible but also have the shortest shelf life due to it being a porous material.

- Fiberglass: Stronger than polycarbonate, fiberglass is cross-laid patterns of fibrous materials bound together by resin, creating a lightweight and rigid structure. Weights on fiberglass helmets will vary on safety certification. Some are thicker laid material which result in more weight.

- Kelvar/Carbon Fiber: Similar to fiberglass, carbon fiber or Kevlar is weaved and adhered by resin. The advantage to using this most expensive material is a lightweight, energy absorbing, flexible design that is extremely strong. Plus it looks pretty badass.

EPS: Expanded Polystyrene Foam is designed to cushion or crush on impact to help prevent head injuries. This is the second line of defense and is the foam you see fitted in the inside of helmets. A hard shell isn't enough to protect the rider, the ability to absorb energy by that foam "crushing" is what keeps the rider safe and free from as much negative energy as possible.

- Multi-Density: Not all EPS is the same, and just like rubber, EPS foam can be made in different densities. A soft foam will absorb the most energy, but collapses quickly. A firm foam doesn't absorb as much energy, but also collapses much slower. An upgrade in helmet safety is to have a dual-density EPS liner. This means you can receive the benefits of both EPS densities and allow the helmet to absorb as much energy as possible.

Liner & Chin Strap: Having a properly fitted helmet sure as hell counts towards safety.

- The interior liner is not tested and graded for safety, however it does play a large part into how a helmet fits. A properly fitted helmet will stay in place and do its job upon an impact. Having a helmet that is too loose will move around or possibly worse, come off.

- The chin strap is tested as that's what keeps your helmet from being ripped from your head. Whether it is a D-Ring, ratchet or magnet system, they all go through testing.

Faceshield / Visor: This may be the one area where the safety standard is the same across the board. This isn't saying all visors are equal as some offer better UV protection, vision clarity or anti-fog/scratch features. What it is saying is that the standard for motorcycle helmet visors is made from poly-carbonate - sort of like the material used to make car headlamps, to construct visors from. Poly-carbonate visors are harder in feel, harder to scratch and usually optically better in terms of distortion than acrylic visors.

Motorcycle Helmet Safety Standards

There are several safety standards for motorcycle helmets, and knowing what they cover can be confusing. Some requirements will overlap, all while having different criteria in other respects.

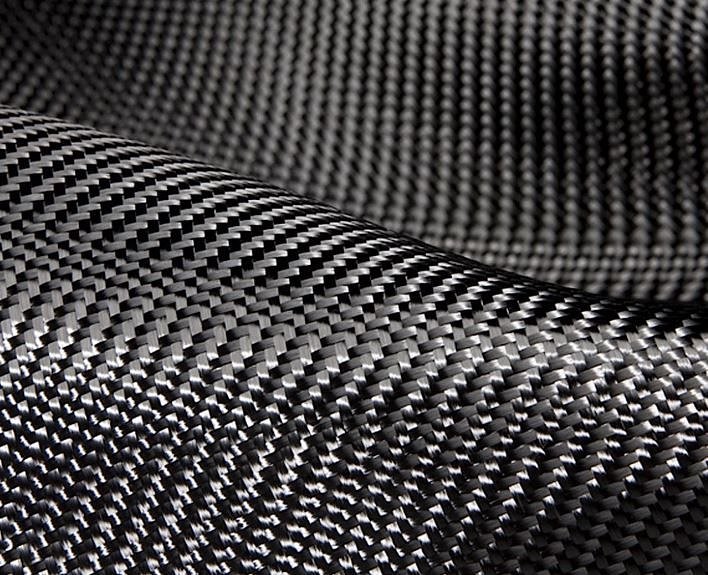

D.O.T. (Department of Transportation FMVSS 218)

FMVSS 218 is the technical standard that defines the minimum criteria that a helmet manufacturer must certify against in the United States. It’s simply known as the D.O.T. helmet standard certification generally.

- Impact Attenuation Test means the helmet is subject to impacts against a rounded and flat anvil after the test helmets have been ‘conditioned’ to reflect four different operating environments. That includes humidity, low/med/high temperatures and water immersion, all of which aims to ensure the helmet will still perform in different extremes of riding conditions.

- Penetration Test where a 6 lb. 10 oz. pointed striker is dropped from 118 inches onto various parts all round the helmet – again against helmets that have been pre-conditioned to reflect four different operating conditions.

- Retention Strap is tested under 50- and 300-pound loads to ensure it doesn’t elongate more than an inch after load.

- Peripheral vision allowed by the helmet is a minimum of 105 degrees from center.

The tests are very similar to the Snell Memorial tests, but the judged values are slightly different on criteria for impact, severity, and test equipment used. The Snell certification is more difficult to pass than the DOT testing.

One additional note is that the manufacturer certifies their own helmets in their own labs, whereas Snell tests and certifies any helmet submitted to them from any manufacturer.

Snell Memorial Foundation (M-95 / M2000)

The Snell Foundation certification is not a requirement by law in the United States or the rest of the world, and they go above the minimum criteria to thoroughly test helmets in many respects. Beyond motorcycle helmets, they test for bicycling, karting, and professional motorsports. Below are the safety features they test for:

- Impact Testing: The impact test uses controlled impacts to simulate different impact surfaces. The object is to measure gravitational (G) force or acceleration. If the peak acceleration in any test exceeds a value, the helmet is rejected.

- Positional Stability (Roll-Off) Test: A head form is mounted so that it points face downward at an angle of 135 degrees. The helmet is placed on the head form and the straps and buckles adjusted to obtain a best fit condition. A weight is connected via wire rope and dropped from a determined height. The helmet is turned 180 degrees and the test conducted again. The helmet may shift, but must not roll off the head form to pass the test.

- Dynamic Retention Test: The helmet is placed on a head form with the chin strap fastened under a device representing the jaw. The jaw piece has a 23 kg weight applied for around one minute. The retention system is tested by simultaneously removing the 23 kg weight and applying a 38 kg mass in an abrupt guided fall. The retention system fails if it cannot support the mechanical loads or if the maximum instantaneous deflection (stretch) exceeds 30 mm (1.18 inches).

- Chin Bar Test: The test helmet is attached to a base with the chin bar facing upward. A 5 kg weight is dropped to hit the central portion of the chin bar. Maximum downward deflection of the chin bar must not exceed the stated distance.

- Shell Penetration Test: The test helmet is attached to a base. A sharp-pointed 3-kg object is dropped from a prescribed height. The test striker must not penetrate the helmet or even achieve momentary contact with the head form inside the helmet.

- Faceshield Penetration Test: The faceshield (also called a visor) is attached to a test helmet and shot along the center line in three separate places with an air rifle. The rifle shoots sharp soft lead pellets at speeds approximately at 500 kph (310 miles per hour). The pellets must not penetrate the visor for it to pass the test.

European Standard 22.05 ECE

ECE "Economic Commission for Europe" is the European standard and very similar to the DOT and Snell testing. The values and tests vary slightly on most criteria, and it also adds a retention standard testing for slipping, abrasion, retention, and durability. ECE also subjects the helmet to various environmental conditions including solvents, low and high temperatures, ultraviolet light, humidity and moisture. Testing is also supposed to be carried out using the helmet size which is determined to be weakest. ECE testing involves taking a batch of large and small sized helmets from the first production batch as well as continuously testing throughout the production run.

Chinstrap Test: The chinstrap is tested to ensure that it won’t slip loose, stretch or break under an applied load. They connect the helmet to a test rig that tries to pull the helmet off the head from the back to make sure the chinstrap does its job effectively.

Faceshield / Visor: While the same as most helmets the ECE tests for scratch and abrasion resistance, refraction, light transmission, opening angle, defects and field of vision. If the manufacturer claims the visor is anti-fog, then they test for that, too.

Shell Penetration: ECE tests impact resistance at various points around the helmet including the side, front, rear, crown and chin guard. ECE even goes as far to test the reflective properties of safety stickers too.

European BSI 6658-85

While not as widely known, Europe has a second standard that helmets are measured by, and it is very close to Snell testing. Passing values on certain tests vary slightly from the Snell standard, but many of the categories list the values as the “same as the Snell M2005 test” as a reference. The BSI tests also incorporate the chin strap slippage, retention, and abrasion testing seen on the ECE 22/05 testing.

SHARP

SHARP is an independent crash helmet safety test funded and run by the UK government that puts ECE 22.05 approved helmets through a more rigorous extra test and incorporating a rating system only available for helmets sold in the UK. It measures standards and rates helmets with a star rating system instead of a pass / fail result. The ratings are shown from a 1-star (lowest) to a 5-star (highest).

All of this means that they are rating helmets based on "real world" tests and applying a star system to them based off of their findings. Kind of like Yelp, but for helmets.

Helmet Selection: SHARP only test helmets they’ve bought from shops themselves so there’s no potential manufacturer interference. They buy helmets in various sizes to make sure the results reflect a range of sizes, and run 32 impact and oblique impact tests on them.

Tested at Speed: Tested at three different speeds (slow, med & fast) SHARP impacts the helmets against a flat and angled surface to try and give an indication of how they’d perform against real-world flat and pointy surfaces.

Real World Rotation: Due to rotational forces equating 60% of casualties, SHARP runs the ‘oblique tests’ to test friction performance for when you impact a surface at an angle and assess how much rotational force will be transmitted through to the rider’s brain.

Rating system: SHARP then compares the results data against ‘real world injury data’ to arrive at their own SHARP rating out of 5 stars.

Motorcycle Helmet Fit

Regardless of what standards it meets, no helmet will provide you with good protection if it doesn't fit properly. Here's how to make sure your helmet fits right.

How to Inspect Your Motorcycle Helmet

Tips for checking your helmet.

More Resources:

- https://www.nhtsa.gov/sites/nhtsa.dot.gov/files/tp-218-07.pdf

- https://www.unece.org/fileadmin/DAM/trans/publications/WP29/Leaflet_Helmets.pdf

- https://shop.bsigroup.com/ProductDetail/?pid=000000000030140499

- https://www.smf.org/

Membership

Membership